1、 Overview

In the dismantling process of waste household appliances, the dismantling process of refrigerators is the most complex and requires the highest dismantling technology. In the past, large dismantling enterprises in China often used refrigerator dismantling lines imported from Germany or Taiwan, which were expensive and had inconvenient after-sales service. Taizhou Qiyi Environmental Protection Equipment Technology Co., Ltd. has developed the sixth generation refrigerator dismantling and recycling line based on its years of experience in home appliance dismantling and absorbing advanced foreign technology. After two years of development, the line has been appraised by industry experts and well-known dismantling enterprises, and has reached the international leading level.

2、 Equipment composition

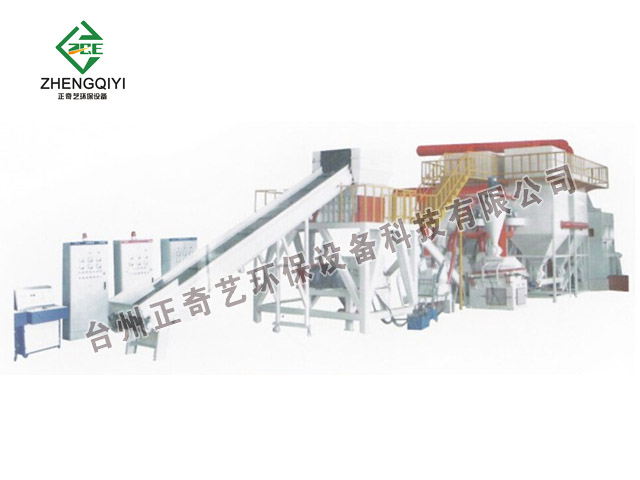

It is composed of pneumatic flap feeding device, refrigerator disassembly fluorine collection part, refrigerator disassembly fluorine extraction platform, power conveyor, roller conveyor, tunnel refrigerator feeding conveyor, four shaft chopper, conveyor, metal plastic separator, iron separator, eddy current separator, dust collector, belt conveyor, foam crusher, foam compressor, electric control system, etc.

1、 Technical Introduction

The harmless treatment and resource recycling equipment for waste refrigerators is a complete set of equipment for dismantling and processing refrigerant containing household appliances such as waste refrigerators and air conditioners. Including pre-processing station, fluorine extraction station, primary whole machine crushing, secondary crushing and separation, resource classification and recycling device, etc. On the basis of drawing on foreign experience, this equipment pioneered the integration technology of two-stage crushing and eddy current crushing separation. It has the characteristics of high automation, high processing efficiency, low operating cost, and no secondary pollution, filling the gap in China's waste refrigerator processing equipment and reaching the international advanced level. It has applied for multiple national patents and passed the ministerial level appraisal organized by the Ministry of Industry and Information Technology on January 30, 2010.

2、 Equipment Description

1. Process flow and description

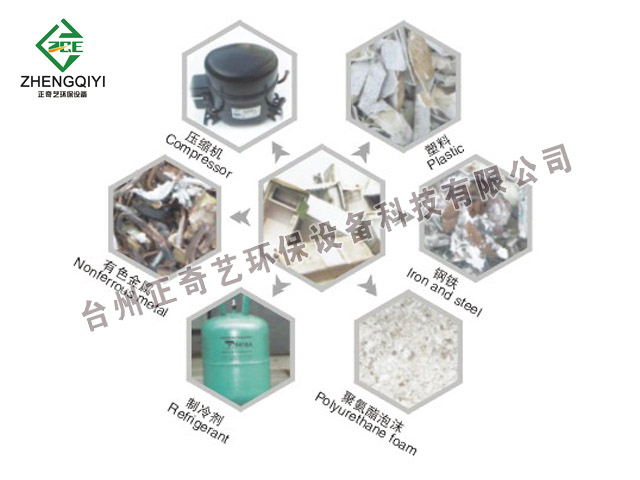

First, the waste refrigerator freezer is manually disassembled to obtain plastic, wire, glass, circuit board, etc., and then the refrigerant is recovered to ensure that the recovered refrigerant will not pollute the atmosphere. Then, the compressor, condenser, etc. are removed, and the box is multi-stage broken. After breaking, the materials are first separated by wind separation to separate plastic and polyurethane foam, then by magnetic separation to separate metal iron, and finally by eddy current separation to separate copper, aluminum, and plastic. The crushing and separation device is sealed in a closed enclosure, and the exhaust gas and dust generated during the treatment process are adsorbed by activated carbon fibers and bag dust removed by a high-pressure fan before being discharged through an exhaust pipe.

2. Main equipment composition and parameters

The equipment consists of pretreatment system, whole machine crushing system, crushing and dissociation system, iron removal system, non-ferrous metal separation system, foam volume reduction and recovery system, tail gas treatment system, safety system and automatic control system.

System name | Function Description |

pretreatment system | Including dismantling workbench and refrigerant recovery device, used for recovering refrigerant, manually assisting in dismantling compressors, and sorting easily removable plastic parts |

Crushing system | Including hydraulic feeding, forced feeding, belt conveying and crushing equipment, used for material conveying and whole machine crushing |

Integrated dissociation system | The original integrated equipment for efficient material crushing and polyurethane foam separation can realize the separation of polyurethane foam |

Iron removal system | Including a magnetic separator, used to remove iron based substances from materials |

Nonferrous metal separation system | Used for separating non-ferrous metals such as copper and aluminum from plastics |

Foam volume reduction recovery system | Including foam volume reduction equipment, which is used for further crushing of foam to make foam pore gas escape and subsequent packaging and transportation |

Security system (optional) | Including spray, nitrogen spray and cyclopentane detection equipment to ensure the safe operation of the production line |

Exhaust gas treatment system (optional) | Including bag filter and activated carbon adsorption device, ensuring that the exhaust emissions meet national standards |

automatic control system | Including video monitoring and automatic control equipment, improving the automation level of the production line and reducing operational difficulty |

3. Main technical parameters

Our company can provide three different specifications of equipment, with the main parameters as follows:

Specification and model | RF-Ⅰ | RF-Ⅱ | RF-Ⅲ |

processing capacity | 10-12台/h | 25-40台/h | 40-60台/h |

Equipment power consumption | 120 Kw | 260Kw | 500 Kw |

Power requirements | AC380V,50Hz | AC380V,50Hz | AC380V,50Hz |

cover an area | 200 m2 | 320m2 | 500 m2 |

operator | 5人 | 6人 | 8人 |

Collection rate of polyurethane foam | >90 | ||

Steel recovery rate (weight%) | 98 | ||

Recovery rate of non-ferrous metals (copper, aluminum) (weight%) | ≥96 | ||

Plastic recycling rate (weight%) | ≥95 | ||

Plastic recycling rate | ≥95 | ||

3、 Safety and environmental protection indicators

Safety indicators: All transmission equipment is placed in a closed enclosure, and isolated operation, video monitoring, and electrical linkage control system are used to protect the safety of operators; We have adopted technologies such as negative pressure adsorption, nitrogen protection, automatic spraying, online monitoring of cyclopentane, online monitoring of dust, automatic alarm control, and online monitoring of temperature to ensure that the dust concentration, cyclopentane concentration, and temperature are within a safe range, ensuring the safe operation of the equipment.

Environmental indicators: This equipment adopts mechanical and physical processes, and does not produce any wastewater during the treatment process; The generated noise is below 85dB (A) after enclosure and noise reduction measures, which complies with the General Technical Conditions for Light Industry Machinery (GB/T 14253-2008); The exhaust gas passes through bag dust removal and activated carbon fiber adsorption equipment, and is centrally discharged through pipelines. The particulate matter emissions comply with the third level standard of the Comprehensive Emission Standards for Air Pollutants (GB16297-1996).

4、 Characteristics and advantages

This device has the following characteristics and advantages:

1. The process of combining manual assisted disassembly and mechanical crushing and separation has the characteristics of good resource separation effect, high equipment processing efficiency, low equipment price, low processing power consumption, and good safety and environmental performance, which is more suitable for the current situation in China.

2. With complete environmental protection measures, no wastewater is generated, and the exhaust gas can meet national standards after treatment; The noise during the operation process is lower than the national standard, and there is no dust generation, with good operating conditions.

3. The equipment has good safety performance and adopts video monitoring and whole machine linkage control to ensure safe and stable operation of the equipment.