Explain: |

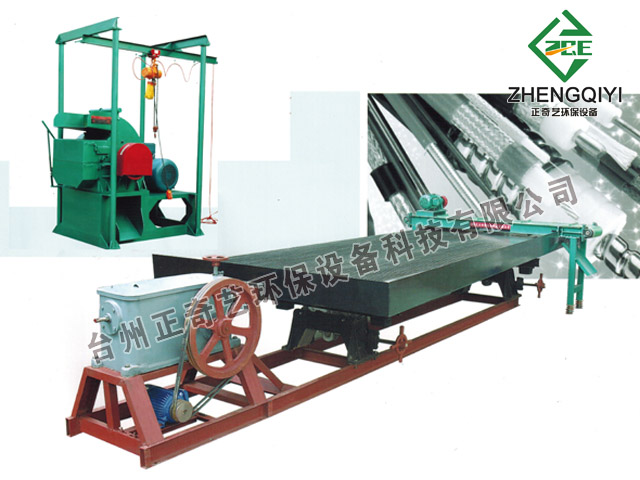

Resource recycling equipment for harmless treatment of waste motor rotors. Dry crushers, strong magnetic roller separators, and airflow separators are used to crush and sort waste electronic rotors. Waste motor rotors that are difficult to disassemble manually are processed by professional equipment to obtain renewable resources. The entire process is carried out under negative pressure.

This device transports manually sorted materials (rigorously mixing large shafts, bearings, gears, large hard iron blocks, etc.) to the crusher for crushing through a conveyor. The crushed mixture is transported by a conveyor to a strong magnetic roller sorting machine to separate non-ferrous metals (mixed materials) and silicon steel sheets (iron sheets). The copper mixed materials are then transported by the conveyor to a crusher for further crushing, and then sorted by an air flow sorting machine to obtain metallic copper and non-metallic materials. A pulse dust removal system was installed during the crushing and sorting process, effectively solving the problem of dust emissions. Machine parameters: Equipment external dimensions | 24000*6500*5000MM | Feed size | ≤100MM | Processing capacity | 800-1200KG/H | separation efficiency | ≥97% | collection efficiency | ≥99% | Total power of the entire production line | 134.8KW |

|