Product Code: 011

Product Code: 011

Product model: 918-B type (speed regulating new cable stripping machine)

Detailed Name: 918-B Type (Speed Regulating New Cable Stripping Machine)

(TXECHNICAL PARAMETER) | ||

Processing scope: | Processing diameter | Φ1.5mm---Φ100mm |

Machine dimensions: length X width X thickness | Overall dimension(LxWxH) | 77cm*55cm*118cm |

weight: | Machine weight | 230kg |

Motor power: | Motor Power | 4000w |

Motor voltage: | Motor voltage | 380v |

10 hours/output: | 10H/Production | 200kg-5000kg |

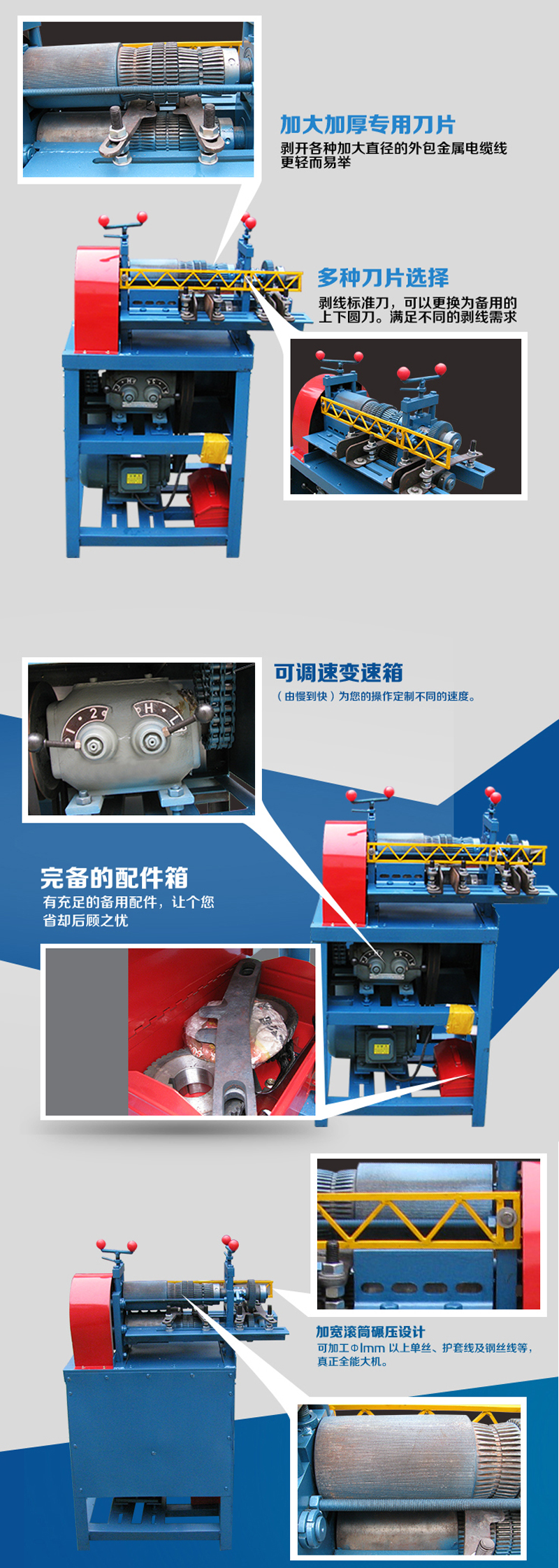

Function: This machine is suitable for various types of 1.5MM-100MM wires and is a widely used wire stripping equipment in the dismantling industry. Roller press, left and right mounted knives (long knives), upper and lower mounted knives (circular blades). The characteristics of this machine differ in that the shaft diameter is increased, the gears are reinforced with double rows, and there are double chains. The upper axis can be adjusted up and down freely during operation.

Operating instructions:

Speed regulation instructions: (from slow to fast) 1st gear L-1, 2nd gear L-2, 3rd gear H-1, 4th gear H-2 (note: the gearbox must be stopped when shifting gears)

The 1.918-B wire stripping machine is relatively easy to operate and use, and is currently one of the most widely used large-scale multifunctional wire stripping equipment.

2. Start the motor and the transmission will drive the spindle to work. The biggest feature is the ability to adjust the upper shaft up and down freely, and to process rubber metal cables with a maximum diameter of 100mm.

3. In terms of operation, there are several situations worth noting about this machine:

① When the machine is working, special attention should be paid to the safety of both hands. When processing sheathed wires and horizontal head operations, the operator's mind should be focused, and a safety cover must be installed in the middle part.

② When processing sheathed wires and cables of various grades, the pressure should not be too tight, and overloading should not be carried out to avoid affecting the service life of various parts.

③ If the material cannot be driven during feeding, check whether the belt is loose, whether the pressure is too tight, or whether the position of the knife is in the wrong direction.

④ If this machine is operated under heavy load for a long time, the oil level of the transmission should be checked every quarter, and the four teeth at the transmission shaft should be lubricated with butter every shift.

⑤ The four Z208 shafts of the upper and lower main shafts should be regularly inspected for bearing and shaft travel, as well as for bearing damage. If this phenomenon occurs, it should be promptly dismantled and repaired. Otherwise, if used continuously, it will cause the shaft to easily break.

⑥ When lifting the upper axis for work, the height of both sides should be relatively parallel.

⑦ The four lifting screws of the transmission and the four lifting screws of the motor should be adjusted one by one frequently to check for looseness. If this is the case, the tension of the chain and V-belt should be adjusted and tightened in a timely manner. When adjusting, the gearbox or motor should be relatively parallel and not too tilted.

Note: Pay attention to safety during production operations.