Product number: 004. No. 006

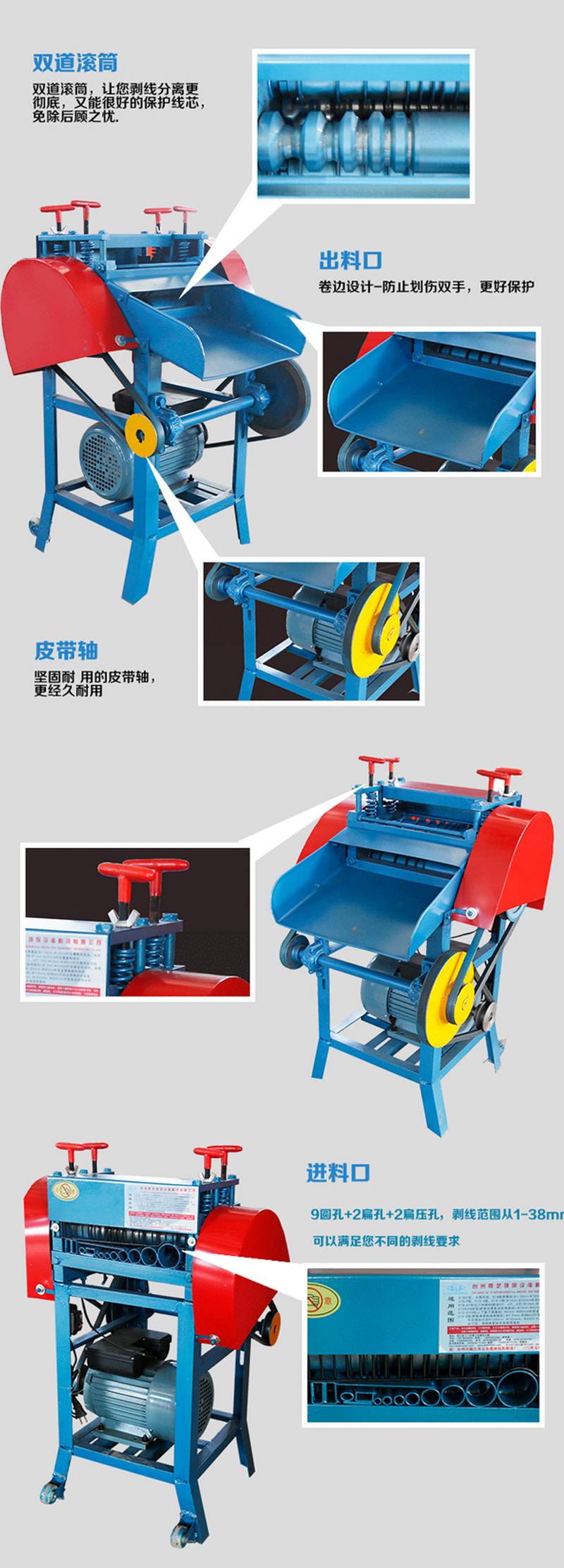

Product model: 918-AF type 3/AF type 5 (double channel double knife cable stripping machine)

Detailed name: Double channel double knife cable stripping machine.

Technical Parameters (TXECHNICAL Parametric)

Processing range: Processing diameter Φ 1mm - Φ 35mm

Machine dimensions: Length X Width X Thickness Overall dimension (LxWxH) 54cm * 52cm * 84cm

Machine weight: Machine weight 89kg

Motor power: Motor Power 1500w. 2200w

Motor voltage: Motor voltage 220v, 380v, 110v

10 hours/production: 10H/production 200kg-1000kg

Function: This machine is suitable for various types of wires, single wire and loose wire cables, and can achieve automatic separation effect. It is mainly aimed at the difficulty of dismantling after the plastic becomes hard in cold winter weather. For example, the front and rear double knife wire stripping machine can reduce manual work and increase production. It is currently a widely used wire stripping equipment in the dismantling industry

Operating instructions:

1. Start the motor and check if it is running normally. When feeding, check the diameter of the rubber cables wrapped around each gear and feed them one by one.

2. In order to make the blade durable for a long time, the joint of the rubber cable should be cut off when feeding to prevent the blade from breaking due to a notch.

3. If there is excessive depth and wire breakage after the feed is discharged, pay attention to the following situations:

① Adjust the tightness of the M12 screws on both sides of the blade shaft on the feeding gear;

② Check if the position is placed incorrectly during feeding;

③ Check if the blade has been replaced and if the edge is too sharp. Use a specialized oilstone to slightly trim it until it is moderately adjusted.

4. If the rubber has been peeled off after feeding, but the copper wire cannot be ejected.

There are four main situations:

① If the rolling pattern on the upper shaft is too deep, a special oilstone should be used to grind the upper shaft, but excessive grinding is not allowed. Excessive grinding can easily cause oily cables to be difficult to transmit;

② Is the spring pressure too loose? The pressure should be tightened and stopped as soon as it can be released;

③ If the diameter of the wire is too small or the gap between the upper and lower shafts is too large, the gap between the two shafts should be adjusted to 0 4---0 . 6mm ;

④ The processed rubber cable has already heated up, and the copper wire cannot be ejected.

5. If the pressure gear cannot drive the cable through after feeding and the material stays in the middle, there are several situations that may occur:

① Check if there is any looseness in the belts of each gear;

② Check if the spring pressure on both sides of each gear is too tight and there is no pushing force. The pressure should be relaxed;

③ The cable is too oily, causing the two shafts to slip. The two shafts should be wiped dry regularly (when wiping, please pay attention to safety if the machine is running).